Gutters play a crucial role in protecting your home by channeling rainwater away from the foundation. When they develop leaks, it can lead to significant damage.

You might wonder whether Flex Seal, a popular waterproofing solution, is effective for sealing gutter seams. While Flex Seal can offer a temporary fix for small leaks, it is not generally recommended as a long-term solution for gutter seams.

Flex Seal is marketed as a versatile product that can create a waterproof, airtight seal. Applying it to clean and dry surfaces can provide a short-term patch, especially in emergencies. However, many gutter professionals, see https://guttersofwestpalmbeach.com/, do not recommend Flex Seal for permanent repairs. Reliable gutter sealants are designed to withstand various weather conditions over time, ensuring the longevity of your gutters.

Understanding how Flex Seal works can help you decide if it’s the right choice for your situation. Some users report success in sealing minor leaks using Flex Seal, making it a quick fix for small issues. If you’re looking for a more durable solution, exploring traditional gutter sealants may be the better approach.

Understanding Gutter Seams and Common Issues

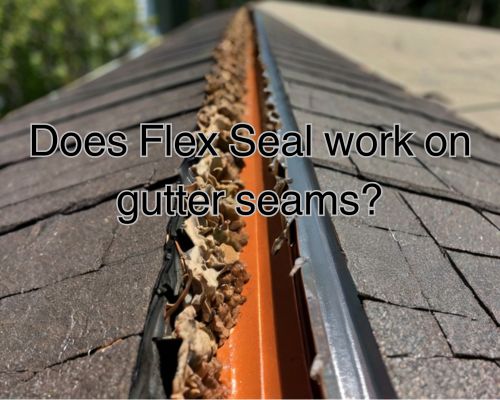

Gutter seams are critical for the efficient functioning of your drainage system. Over time, these seams might suffer wear and tear, leading to leaks that can result in significant water damage to your property.

Types of Gutter Materials and Associated Problems

Gutters are typically made from materials like aluminum, steel, copper, and vinyl. Each has unique benefits and potential issues.

- Aluminum: Lightweight and rust-resistant but can be prone to denting and leaks at seams if not properly sealed.

- Steel: Durable but susceptible to rust, which can compromise seams.

- Copper: Long-lasting and resistant to rust, but expensive and can suffer from oxidization that affects seams.

- Vinyl: Affordable and easy to install. May develop cracks in extreme temperatures, leading to leaks.

Understanding your gutter material is essential in addressing seam-related problems effectively.

Typical Gutter Seams and Leak Points

Gutter seams are common at corners, downspout junctions, and joining sections. These points are vulnerable to leaks due to stress and movement.

- Corner seams: Often experience leakage because water flow is directed towards one point, increasing pressure on these joints.

- Sectional seams: As gutters expand and contract with weather, the joints between sections can loosen, leading to leaks.

- Downspout junctions: Improper sealing at this connection can allow rainwater to escape, causing it to flow down the building’s foundation rather than away.

Regular inspection and maintenance of these areas can help you address potential problems before they lead to significant water damage. For professional works, see https://guttersofwestpalmbeach.com/.

Applying Flex Seal to Gutter Seams

Using Flex Seal on gutter seams can effectively seal leaks and create watertight barriers. Proper preparation of the gutter surface, a methodical application process, and attention to safety measures are essential for optimal results.

Preparation of Gutter Surface for Application

Before applying Flex Seal, the gutter surface must be thoroughly cleaned. Remove debris, dirt, and old caulking.

Use a wire brush or scrub with soapy water, ensuring that the area is clear and dry.

Checklist for Cleaning:

- Remove all debris.

- Scrub with soapy water.

- Dry thoroughly with a clean cloth.

Ensuring the surface is clean maximizes adhesion and enhances long-term performance.

Step-by-Step Guide to Apply Flex Seal

- Shake the Can: Vigorously shake the Flex Seal spray can for about a minute to mix the contents well. This ensures even application.

- Mask Surrounding Areas: Use painter’s tape to cover areas you don’t want Flex Seal to reach. This helps in achieving a clean application.

- Spray Technique: Hold the can 8 to 12 inches from the gutter seam and spray in a steady, sweeping motion. Apply an even coat, ensuring the flex seal covers all areas of the seam.

- Multiple Coats: For improved effectiveness, apply several coats. Wait for adequate drying time between applications as specified on the Flex Seal label. This builds up a solid waterproof barrier.

- Drying Time: Allow the final coat to dry completely. Check the manufacturer’s instructions for specific drying times.

Safety and Environmental Considerations

When using Flex Seal, prioritize safety. Ensure adequate ventilation.

The spray can emit fumes that need proper air circulation. So, make sure you have enough ventilation. This is especially important if you are working indoors or in enclosed spaces.

Personal Protective Equipment:

- Wear gloves to protect your hands.

- Use safety goggles to shield your eyes.

Dispose of empty cans responsibly. Follow local regulations to minimize environmental impact. Consider the non-toxic nature of the product, but still handle with care. Stay informed about the material safety data sheet (MSDS) for detailed safety info.